Hydrodynamic Testing

No other suppression provider has performed as many hydrodynamic testing programs as our team. When a client comes to us with a request for testing, we use our experience to develop a customized program aimed at achieving technical objectives and minimizing cost. Our team helps identify the best facility for the work scope and assembles a sample matrix of test runs to gather the necessary raw data. VIV Solutions® technicians can design and construct the rigging for the test, as well as interface with local personnel to ensure a seamless kickoff to the campaign. Once testing activities are complete, our engineers analyze the data sets and prepare a detailed report of the findings.

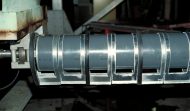

An abbreviated sample list of various subjects we have previously studied is shown below:

|

|